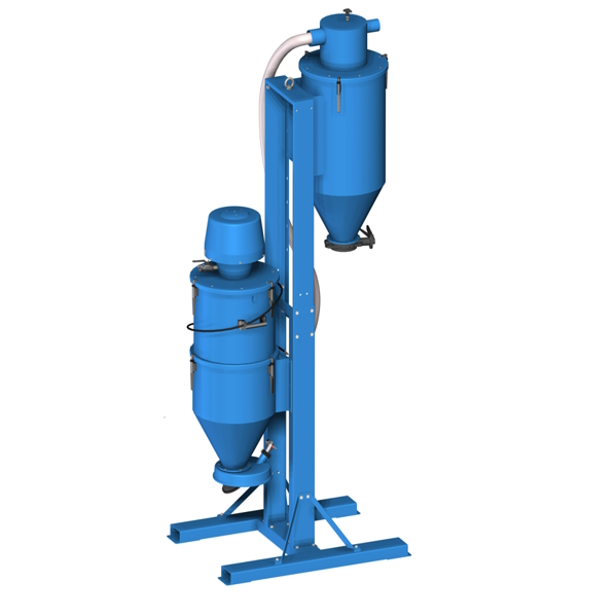

722A, configurable

A powerful dust collector, excellent high vacuum for suction over long horizontal and vertical distance

Nederman Pre-separation and Vacuum Transportation Systems pre-separate and discharge dust and granulated material during vacuuming and vacuum transport.

A system can handle dry material like cement, fertilizers, grit, sand, as well as wet material. Collected material can be discharged into tanks, containers, big-bags, on to conveyor belts, escalators etc.

The configuration of modules will be similare to 722A which are aimed for the toughest applications, for example handling a lot of abrasive and heavy material. The robustness of the unit and the power from the reliable ejector makes the unit very suitable for many applications where many industrial vacuum cleaners can not be used. For example to collect blasting material in blasting hall, sand recovery in foundries etc.

Your unit can be configured to meet your specific demands. Different ejectors can be used depending on the demand but also the availability of compressed air. The ejector can be placed on a stationary silo with filter.

Nederman has a range of different discharge valves that can be fitted to the silo for easy discharge of the collected material.

If handling larger quantities of material and in order to make the material handling more effective Nederman recommends using a pre separator before the vacuum unit.The 722A is a complete unit including a pre separator.

To configure your 722A you may only choose modules listed in this document and with mfc (module for configuration) in title.

Filterside:

1. Select ejectormodule depending on required vacuum and air flow.

2. Select filtermodule depending on filter capacity.

3. Select silomodule.

4. Select disposal option, bagholder and discharge valve.

Separatorside:

1. Select coarse grain separator.

2. Select silomodule.

3. Select discharge valve.

4. Select frame.

5. Select hose for connection between vaccum cleaner and separator.

6. Select joint sleeve depending on coarse grain separator and hose.

7. Select cleaning equipment.

Choose how to control your butterfly valve:

1. Electric controlled

- You need a namur valve, solenoid valve recommended for the ejector size you choose and a suitable control box.

2. Air controlled

- You need a namur valve.

Hose for air supply to the namur valve is not supplied by Nederman.

Ensure you meet all requirements for your modules.

- Robust and efficient self-cleaning filter

- Very powerful and reliable ejector as vacuum producer

- Suitable for heavy and/or abrasive material

- Control system with many different functions is available as an accessory

Technical data

| Filter Area (m²) | 3,15 |

Enquire Today

Established in 1970, AE Industrial & Air Equipment Ltd is a leading company engaged in the supply, installation and maintenance of compressed air, pneumatic controls and product finishing equipment and systems.

Complete our enquiry form and a member of our sales team will be in touch as soon as possible.