Metalworking Industry

Compressed air in the metalworking industry

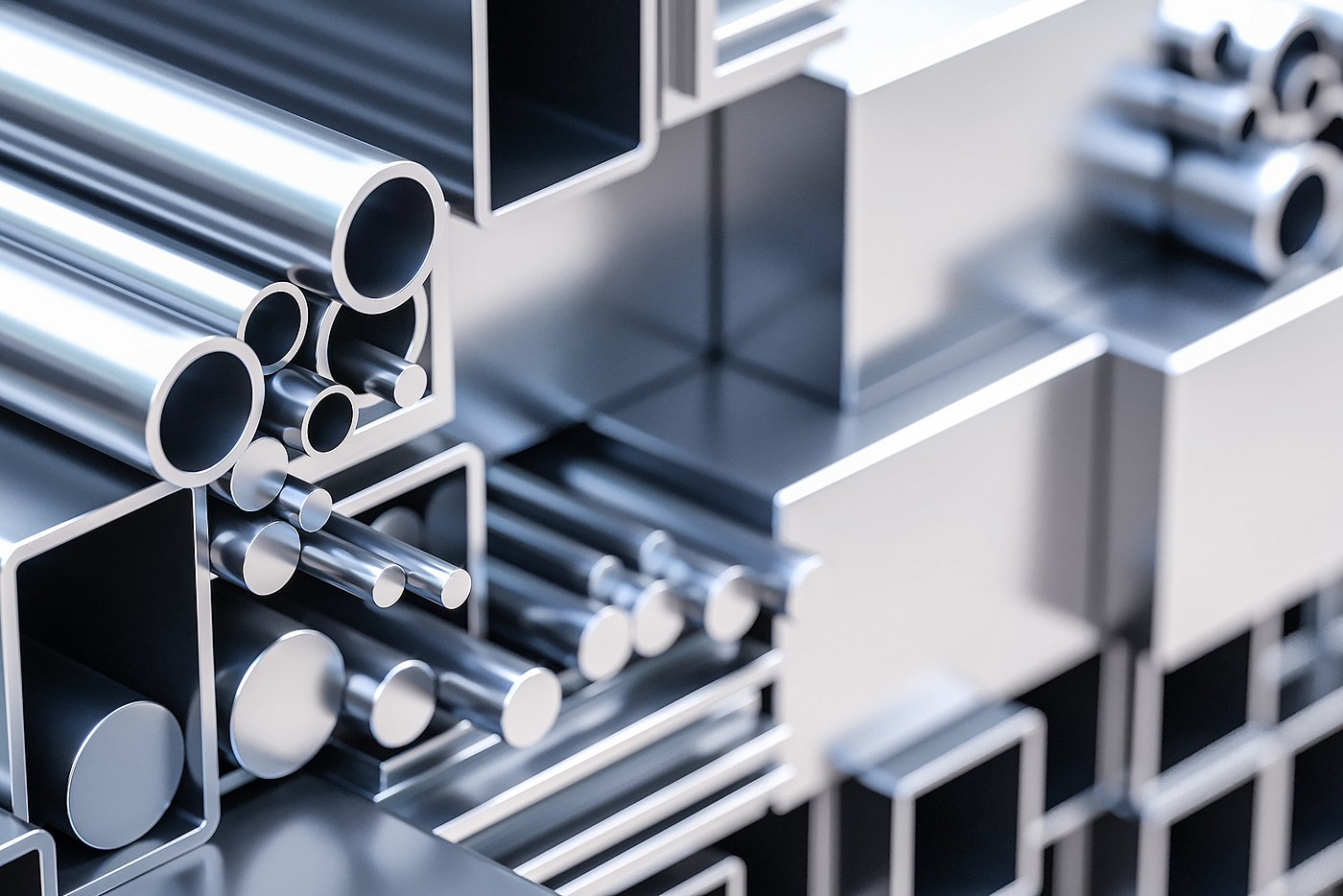

The metalworking industry encompasses both the production and processing of metal. This means that the manufacturing of steel and non-ferrous (NF) metals, foundries and metalworking are all part of the metalworking industry.

The branch is one of the energy-intensive industries. Compressed air is used as a flexible medium in many production processes in metalworking and metal-producing operations. Compressed air is an often underrated parameter for reducing energy intensity and thus increasing energy efficiency.

Alongside the importance of compressed air for energy efficiency, the right compressed air quality is crucial to avoiding problems in production and faults in the final product. By treating compressed air according to their requirements, metal-producing and metalworking industries can reduce costs, improve energy efficiency as well as avoid scrap and production standstill.

Applications in industry

Steelmaking

Steel is made in two steps in the blast furnace: in the first step, iron ore is reduced to pig iron, in the second step it is processed into raw steel in the converter. Compressed air is used during the first step. The blast furnace is charged from the top, which means layers of coke and iron ore alternate in the blast furnace. At the bottom, so-called hot blast air is blown in through tuyères. The term hot blast air described heated compressed air enriched with oxygen and hydrocarbon fuel. This is necessary for effective iron melting.

Compressed air is also used for air cooling. Cooling influences the properties of the steel, thus special demands are made on steel cooling and the medium used. One example is accelerated cooling, which takes place in moving air (falling air).

Sandblasting

During the production process of metal and metal parts, the surface must be cleared completely of deposits and particles, since this could otherwise have a negative influence on the downstream working processes such as surface treatment. One method used for this is sandblasting, which is also known as abrasive jet machining. This technology is used to free the material from residual paint, soiling and rust, to shape the workpiece and work the surface structure.

Compressed air is used to accelerate the blasting agent passing through the nozzle, since the blasting agent must collide with the surface at high speed for the treatment.

Enquire Today

Established in 1970, AE Industrial & Air Equipment Ltd is a leading company engaged in the supply, installation and maintenance of compressed air, pneumatic controls and product finishing equipment and systems.

Complete our enquiry form and a member of our sales team will be in touch as soon as possible.