Beko Filters

CLEARPOINT® 3eco: the latest filter generation

The latest generation of the CLEARPOINT 3eco compressed air filter series has enabled us to improve our solutions for efficient compressed air filtration even more, we decreased the residual oil content by 10 times after the filter. The differential pressure can be simultaneously reduced by up to 50 % and the energy efficiency can therefore be considerably optimised. For these reasons we are very pleased to add our ECO-Label on this product.

Energy efficient and safe compressed air filtration

Taking advantage of new material and production technologies as well as a flow-optimised, corrosion-protected housing design, CLEARPOINT 3eco provides safe and reliable filtration and a qualitative, improved compressed air with considerably reduced operating costs.

The particularly high separation performance makes it possible to fulfil every compressed air filtration requirement with just 3 degrees of filtration – C (Coarse), F (Fine) and S (Ultra-fine). The new 3eco-filter has of course also been validated by the independent IUTA Institute according to ISO 12500.

Filter elements with low differential pressure reduce operating costs

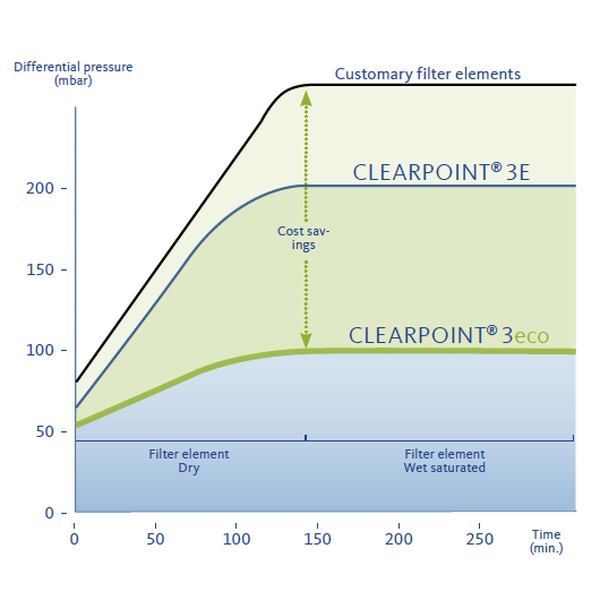

In compressed air treatment, the greatest savings potential lies in the reduction of energy costs. Depending on the utilisation of the system, these can amount to up to 80% of the total costs. The energy consumption is significantly influenced by the differential pressure during the filtration of oil aerosols and particles.

The new CLEARPOINT 3eco filters reduce the operating costs even further compared to the already good CLEARPOINT 3E filters. The energy savings per year are in some cases higher than the purchase costs of the filter elements. And with their oil aerosol separation efficiency of up to 99.95 %, they even increase process reliability.

The graphic shows this for a filter with filtration grade S in size S040 with energy-optimized volume flow.

Innovative design of the filter elements

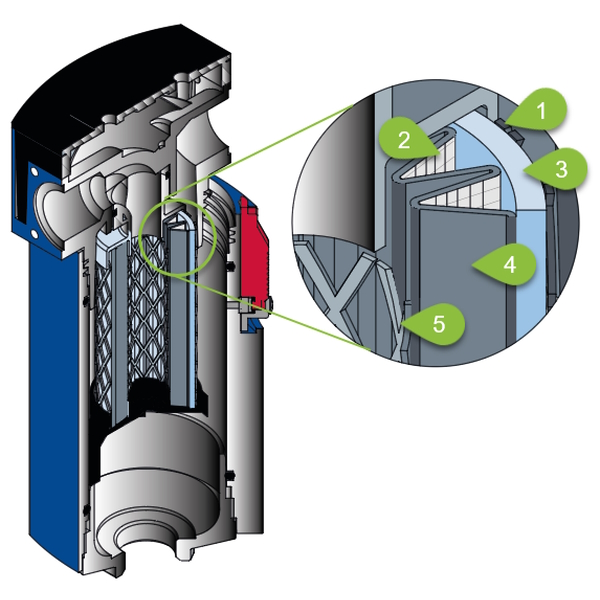

The considerable increase in the performance of the filter elements was made possible by new materials: the new pleating technology (soft pleat) uses the entire filter surface and thus enables higher separation efficiencies at lower differential pressures than conventional pleating technology, in which the pleating tips are coated with an adhesive. The open plastic support fleece (2) keeps the pleated filter material (4) in shape without reducing the filter area. The finest glass fibres in combination with the large filter volume lead to optimum flow velocities in the filter medium and support efficient depth filtration for consistently high separation rates.

The optimal transition from the filter medium to the drainage layer (3) is always ensured, as the drainage layer lies protected behind the outer support cylinder.

Oil- and water-repellent fibre coating leads to optimum transport of the liquid particles through the filter medium.

Inner (5) and outer (1) stainless steel support cylinder protect the filter element in case of pressure fluctuations

CLEARPOINT® W water separator

Water condensates when compressed air cools down in after coolers of compressors or refrigeration dryers. Failure to discharge this water punctually from the compressed air system can result in expensive consequential damage: Pipework corrodes, pneumatic valves, cylinders and tools wear prematurely and the performance capability of the compressed air system is reduced. This results in a lack of process safety and increased costs for compressed air technology.

A water separator extracts the condensate particularly economically from the compressed air. Decisive hereby is the reduction of the flow resistance. What applies here is the lower the flow resistance, the lower the operating costs. The CLEARPOINT W water separator functions with an extremely low pressure difference and thereby achieves the highest separating rates.

Enquire Today

Established in 1970, AE Industrial & Air Equipment Ltd is a leading company engaged in the supply, installation and maintenance of compressed air, pneumatic controls and product finishing equipment and systems.

Complete our enquiry form and a member of our sales team will be in touch as soon as possible.

Full Name