Beko Refrigeration Dryers

Refrigeration dryers: the most economical drying method for any system

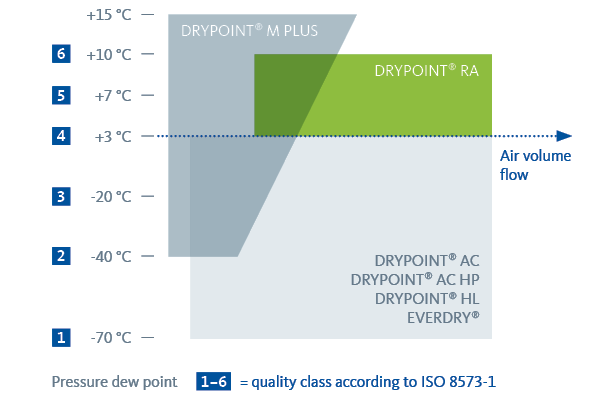

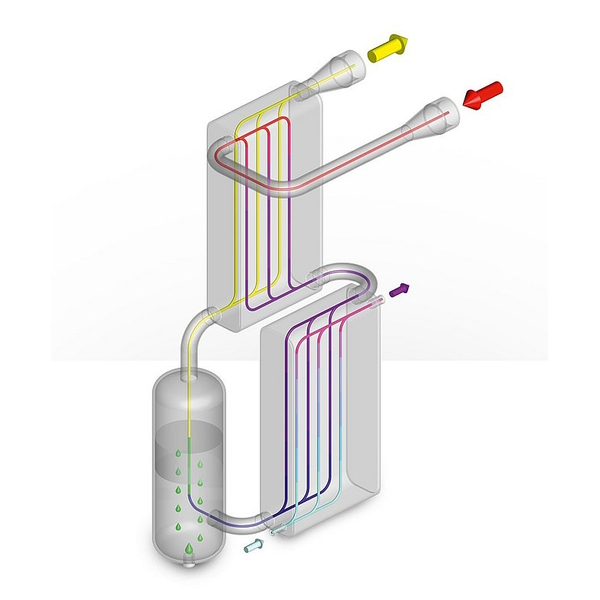

Refrigeration dryers are used in compressed air systems worldwide and represent the current state of technology. Refrigeration drying is the most cost-effective technology for the drying of compressed air: The compressed air is cooled, so that water vapour in the air condensates inside the unit and can be drained off. For fluctuating volume flows, we recommend the DRYPOINT RA eco, as its intelligent controls enables you to make significant energy savings. For applications where stable conditions are a key requirement, the standard DRYPOINT RA direct expansion dryer is the most efficient solution.

Tried and tested, utilised everywhere: DRYPOINT® RA

The DRYPOINT RA refrigeration dryer is the standard solution and therefore always the first choice for applications with stable operating conditions and constant pressure dew points of + 3°C. The large variety of models enable us to always be able to provide you with the correct solution for your requirements. Every one of them impresses with reliable drying, minimal compressed air loss as well as low energy consumption, even with varying work load. The tried and tested design of the DRYPOINT RA enables not only maximum functionality, but also reliable, safe and cost-effective operation.

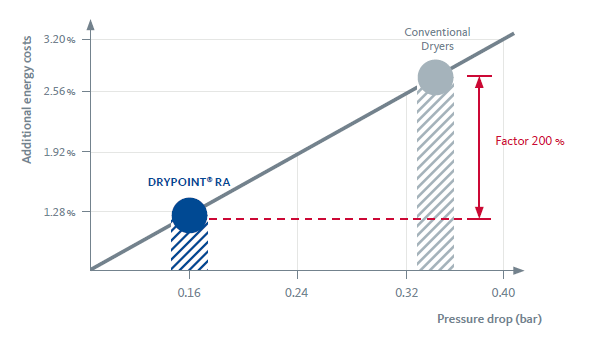

Convincingly efficient with minimal pressure loss

A high pressure drop in the refrigeration dryer must be compensated for by an increased compressor performance and the therefore associated additional energy demand. The consequences are unnecessary energy consumption and significantly higher operating costs. In the case of DRYPOINT RA refrigeration dryers, the pressure drop has therefore been reduced to an absolute minimum. The essential elements here are the flow-optimised heat exchanger, a demister for safe separation and generously dimensioned components, which ensure a low pressure drop of 0.16 bar on average - in full load operation.

DRYPOINT® RA 20-960 eco

- For volume flows < 1,000 m³/h

- Save energy costs with requirement-related switching off for the refrigerant compressor

- Display of percentage-related energy savings

- Potential-free contact for transmitting alarm messages

DRYPOINT® RA 1300-10800 eco

- For volume flows > 1,000 m3/h

- High energy savings with fluctuating drying requirements by utilising the unique combination of frequency control and downtime control

- Implementation of low-vibration and energy-efficient scroll compressors

- Intuitive 4.7” touch screen for simple and rapid function control - also for the integrated BEKOMAT

- Potential-free contact for transmitting alarm messages

- RS485 interface provides external control and monitoring possibilities

- Recording for alarm situations / alarm messages

The refrigeration dryer for high inlet temperatures: DRYPOINT® RA HT

The DRYPOINT RA HT compressed-air refrigeration dryer has been specially developed for applications in which compressed air with high inlet temperatures up to 80 °C must be dried efficiently.

The well thought out and sophisticated, flow-optimised design ensures low-resistance flow for compressed air. The optimised refrigeration compressor technology also ensures low energy consumption with very stable pressure dew point.

Integrated CLEARPOINT® upstream filter with BEKOMAT®

The refrigeration dryer provides maximum safety with minimum energy consumption. The integrated BEKOMAT safely drains the condensate that is produced and with no unnecessary loss of compressed air.

The efficient construction design of the DRYPOINT RA HT compressed-air refrigeration dryer is the basis for cost-effective and safe operation - even with compressed air inlet temperatures of up to + 80 °C.

The refrigeration dryer for high pressure applications: DRYPOINT® RS HP

The DRYPOINT RS HP compressed-air refrigeration dryer has been specially developed for applications in which compressed air in the pressure range of 45 bar/50 bar must be dried efficiently. This is often the case during manufacturing from PET bottles, but also to start diesel units or geological drilling machinery.

Stainless steel plate heat exchanger of the DRYPOINT® RS HP

The sophisticated, flow-optimised design of the stainless steel plate heat exchanger ensures low-resistance flow of compressed air. The optimised refrigeration compressor technology also ensures low energy consumption with very stable pressure dew point.

Enquire Today

Established in 1970, AE Industrial & Air Equipment Ltd is a leading company engaged in the supply, installation and maintenance of compressed air, pneumatic controls and product finishing equipment and systems.

Complete our enquiry form and a member of our sales team will be in touch as soon as possible.

Full Name