Parker Desiccant Dryers

KA-MT 1-8 Series Compressed Air Adsorption Dryer with Activated Carbon Stage

Compact, heatless compressed air adsorption dryers with oil vapour removal for industrial requiring volume flows up to 86m³/h @ 7 barg and dew points of -40°C (-25°C and -70°C options available).

• Pressure dew points down to -40°C (-25°C and -70°C options available)

• Volume flows up to 35 m³/h @ 7 barg (100 psig)

• Pre- and post OIL-X filters installed as standard

• Fully dewpoint dependent controller is possible as an option

• Remaining oil content of 0.003 mg/m³

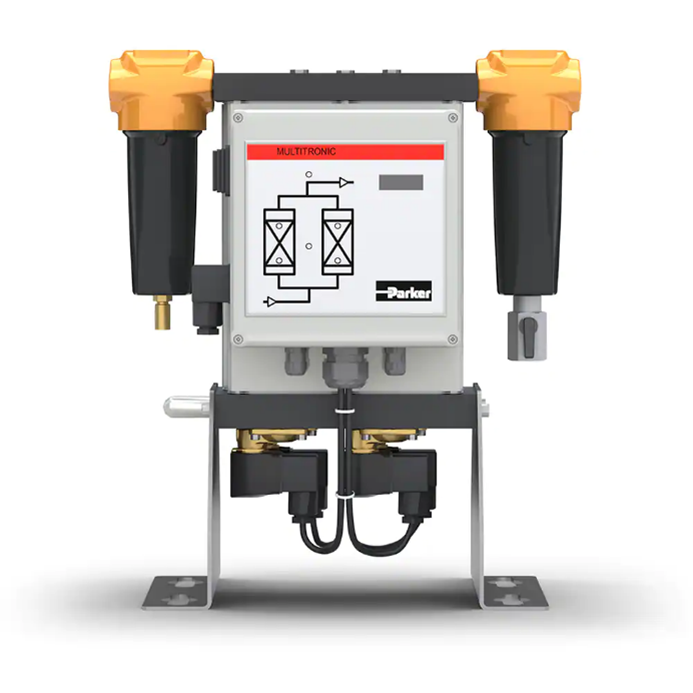

K-MT 1-8 Series Heatless Compressed Air Dryer

Compact, heatless compressed air dryers for applications requiring volume flows up to 86m³/h @ 7 barg and dew points of -40°C (-25°C and -70°C options).

The Parker K-MT 1-8 range of heatless adsorption dryers are designed to dry industrial compressed air reliably and efficiently down to a pressure dew point of -40°C (-25°C and -70°C options available). The units are compact and can be installed either free-standing or wall mounted. They come equipped with integrated high performance OIL-X pre- and after filtration and are capable of volume flows up to 86 m³/h in a system operating at 7 barg (100 psig).

- Pressure dew points down to -40°C (-25°C and -70°C options available)

- Volume flows up to 86 m³/h @ 7 barg (100 psig)

- High performance pre- and after filters installed as standard

- Energy saving dew point dependent switching (DDS) as an option

CDAS HL Medium Flow Heatless Compressed Air Dryer System

Medium flow compressed air treatment systems providing pressure dew points of -70°C, -40°C or -20°C at flow rates up to 300 m³/hr @ 7 barg. Suitable for all industrial compressed air applications

Parker's CDAS HL Clean Dry Air Systems provide clean, dry compressed air in accordance with all editions of ISO8573-1, the international standard for compressed air quality. They are energy efficient and can provide pressure dewpoints of -70°C, -40°C or -20°C with flow rates up to 300 m³/hr (177 cfm) @ 7 barg (102 psi g).

Clean, dry air improves production efficiency and reduces maintenance costs and downtime. Many products claim to provide this, however only CDAS HL Clean Dry Air Systems provide the highest levels of dry compressed air with validated performance.

Features

- Energy saving dewpoint dependant switching included as standard*

- 4 Stages of purification

- Treatment of 7 contaminants (9 with optional WS)

- 3rd Party validated performance

- Pre/post filtration included

- ATEX option available, for use in potentially explosive atmospheres

- Corrosion protected

- Full bore internal flow paths

- Not available for ATEX models.

FBP HL Medium Flow Heatless Compressed Air Dryer System

FDA approved medium flow compressed air treatment systems, providing flow rates up to 300 m³/hr @ 7 barg. Suitable for food, beverage and pharmaceutical compressed air applications.

The Parker FBP (Food, Beverage, and Pharmaceutical) compressed air dryer system provides compressed air treatment with innovative technology and features which deliver 100% validated air quality and world leading standards of efficiency.

Based upon the OFAS platform, the FBP compressed air dryer system adds FDA approval and improved air quality to ensure food beverage and pharmaceutical standards are achieved.

The centre of any compressed air treatment solution is the dryer, its purpose, to remove water vapour, stop condensation, corrosion and in the case of adsorption dryers, inhibit the growth of micro-organisms. Compressed air contamination problems can be simply avoided by installing a Parker FBP high efficiency compressed air dryer system. The packages are suitable for use with any compressor type and are suited to point of use applications.

Typical applications: PET bottling, product handling, food filling machines, nitrogen generation pre-treatment, air knives and packaging.

Benefits

- Validated performance to ISO 7183 and ISO 8573-1 providing confidence in compressed air quality.

- FDA Title 21 CFR certified and EC1935-2004 Exempt, meaning the product is ideal for installation in food, beverage and pharmaceutical processing plants.

- Advanced energy saving technology as standard, along with flow management which provides low differential pressure means significantly reduced energy consumption and lower running costs.

- Enhanced durability and low maintenance requirements result in significantly enhanced uptime, maximum productivity and a longer operational life.

- Reduced energy consumption, consistent performance, lower service and maintenance costs, reduced downtime. FBP are engineered to provide the lowest total cost of ownership of any (heatless) air treatment package.

Enquire Today

Established in 1970, AE Industrial & Air Equipment Ltd is a leading company engaged in the supply, installation and maintenance of compressed air, pneumatic controls and product finishing equipment and systems.

Complete our enquiry form and a member of our sales team will be in touch as soon as possible.